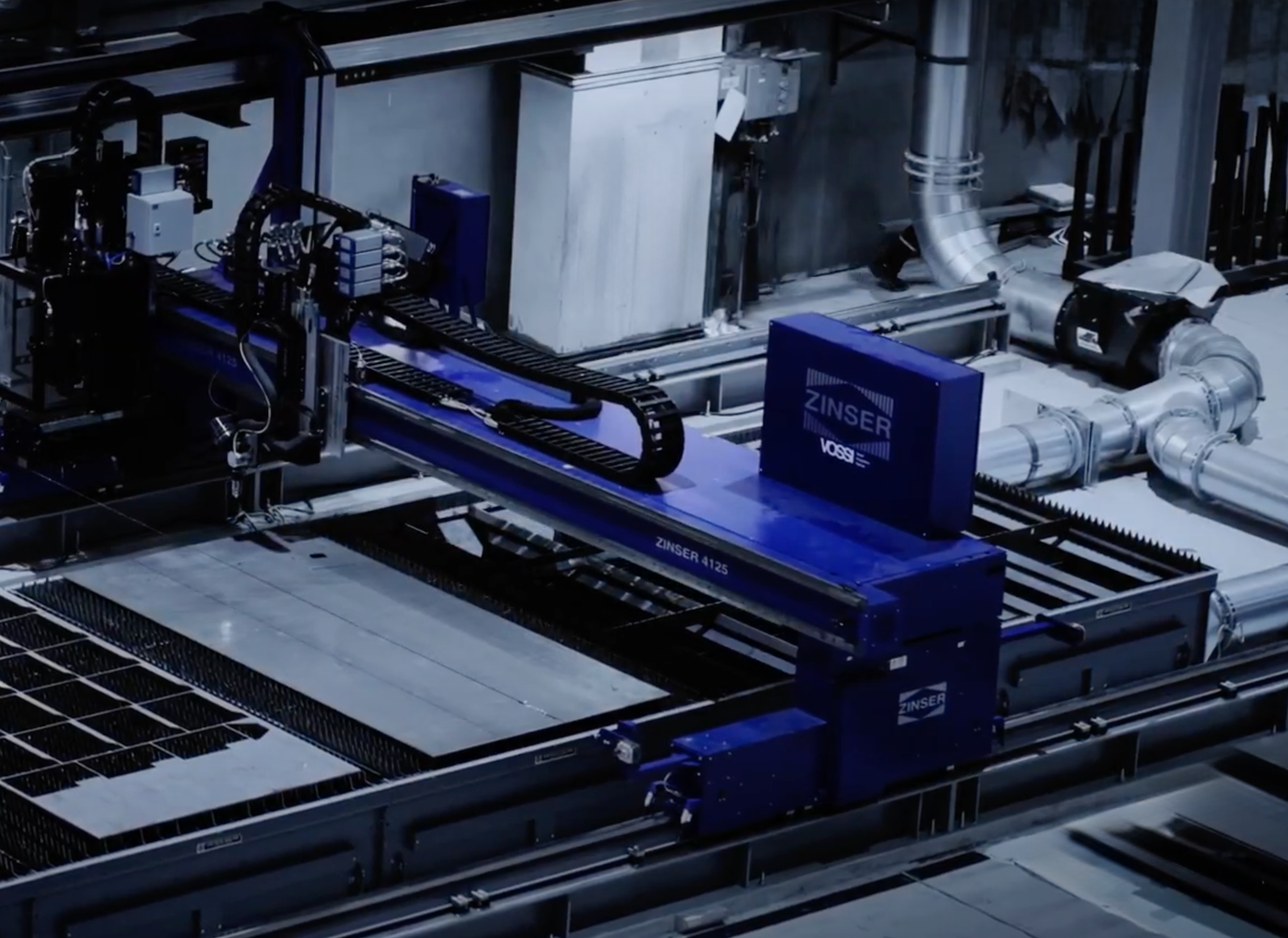

Having our own plasma cutting equipment further enhances our supply reliability and speeds up processes.

“Producing cuts self-sufficiently streamlines production and makes equipment manufacturing more cost-effective. In-house plasma cutting enhances our quality control, which adds its own positive contribution to supply reliability,” says Stairon’s Sales Manager Antti Reivonen.

The 3,000×13,000 mm cutting capacity enables the production of large cuts as well as cuts for heavy steel structures, such as for the mining industry. In addition, the machine has its own drilling unit with an automatic tool changer, so bevels and threads can also be made with the same machine. The drilling diameter is 6–40 mm.

“With the machine’s own drilling unit, the parts can be machined more accurately, as the holes can be made with the same machine – this way, quality is maximized and errors are minimized,” Reivonen adds.

For our customers, the expansion of the offering is reflected in cost-effectiveness, and the machine has already aroused great interest.

“There have been a commendable number of contacts,” Reivonen praises.

Contact Antti for more information!