We turn raw materials in to finished products and plans into reported data

We manufacture processing equipment for various industries with decades of experience, new technology and a data driven process.

We know the lifecycle of an equipment from start to finish - and along the way.

Our solutions scale across industries and from individual products to series.

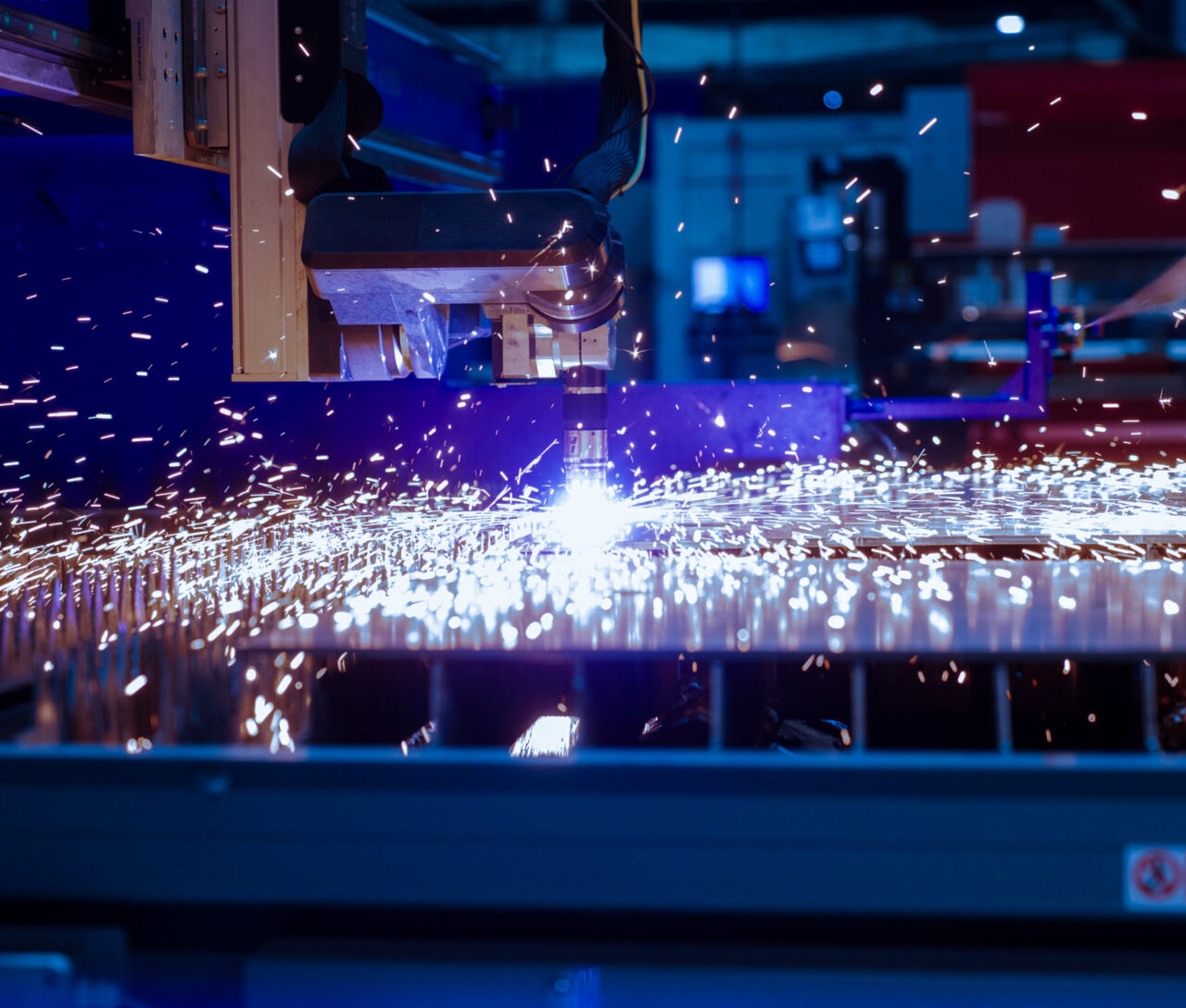

Machine and equipment manufacturing

Whatever you need, we have the facilities, equipment and expertise

Our facilities cover 15,000 square meters of customizable space in which we prepare orders according to our customers’ needs. Our factory has a lifting capacity up to 40 tons. We are a self-sufficient organization in relation to raw materials and expertise. We offer certified quality and service from start to finish.

We manufacture custom made products in series or individual pieces, semi-finished or ready to install. Cost-efficiency and high quality standards are the backbone of our work. If you’re battling a challenge, don’t hesitate to tell us – we’re eager to solve it.

Installation and supply – on site or at our premises

Once the equipment is manufactured and assembled, we are halfway there. We carry out installations for even the most demanding sites. The equipment is tested either at our premises or at a location designated by the customer. Our service includes equipment and instrumentation if required. We have a diverse pool of trusted partners with whom we can implement the special solutions required. We are also involved in commissioning and maintenance if needed.

Stairon deliveries near and far

USA Food industry

Manufacturing of salt pans and salt cages for a cheese processing plant.

FINLAND Energy industry

Manufacturing of flue gas scrubbers and district heating pipelines for power plants.

TANZANIA Mining industry

Mechanical assembly of mining machinery and manufacturing of steel structures for equipment.

NETHERLANDS Automation

Manufacturing of frame structures for transport and welding systems for wind turbine foundations.

CHINA Lifting equipment

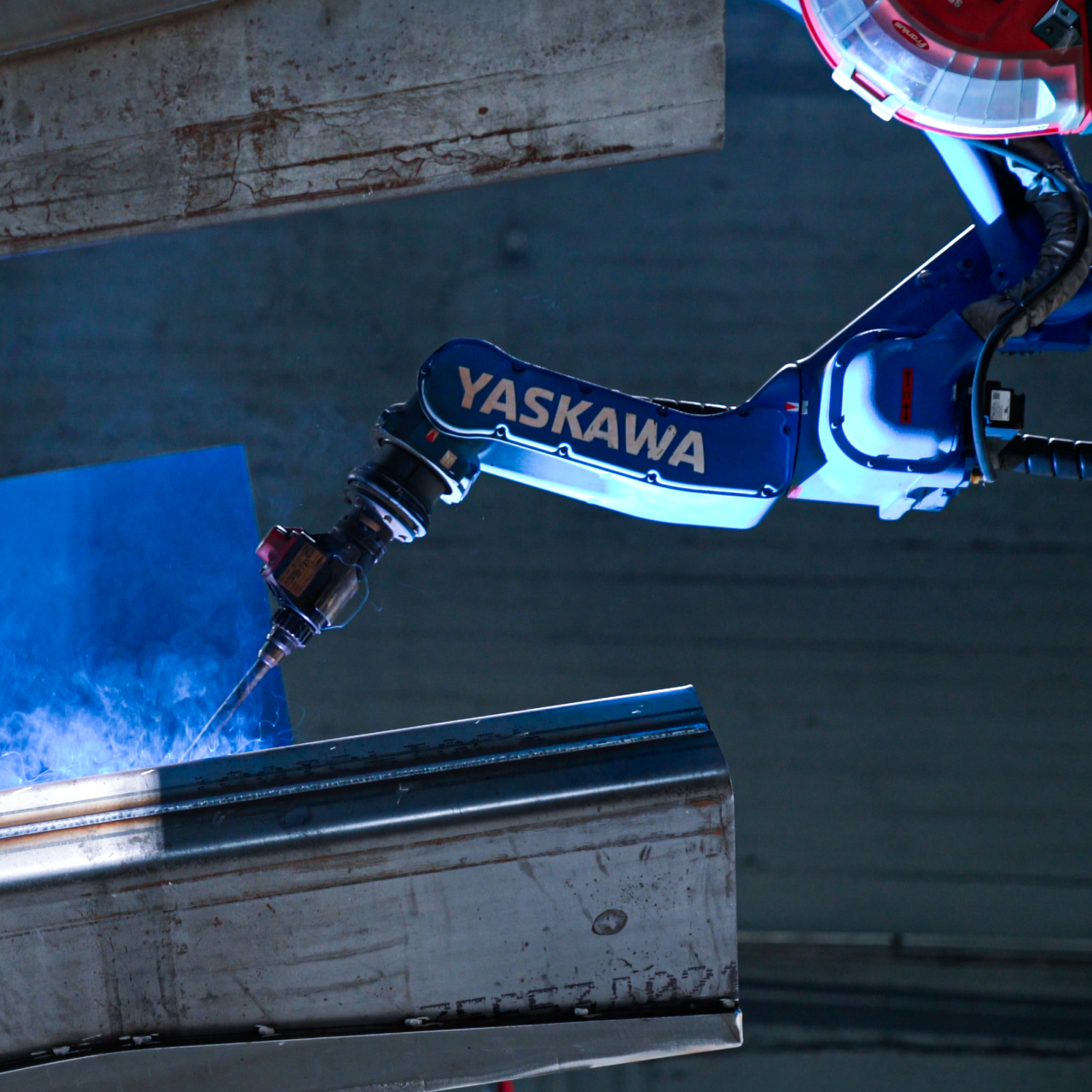

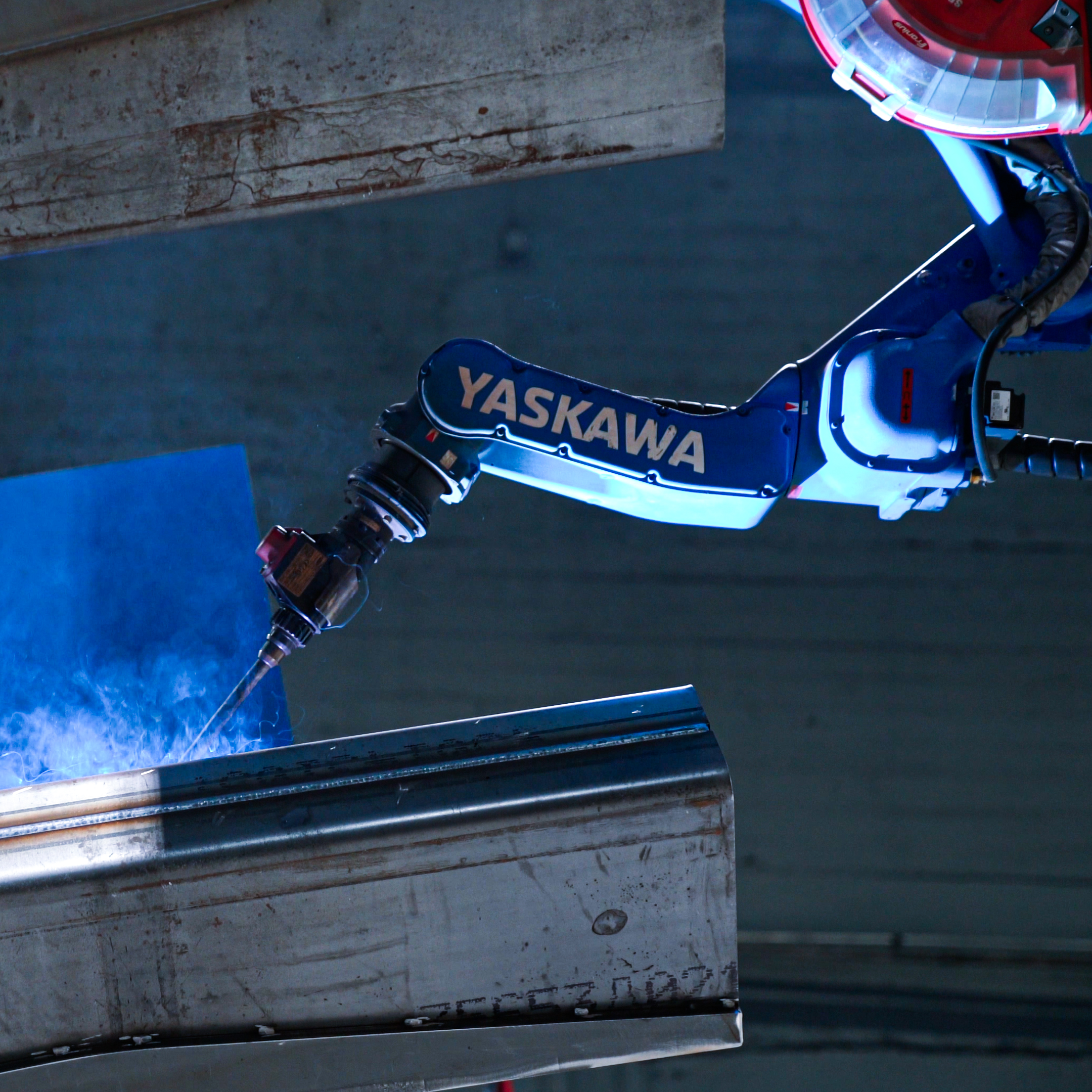

Improving the manufacturability of crane structures through robotic welding.

Product and manufacturing development

The finished product must also be designed

We are a solution provider. When you’re looking for a partner to design manufacturing processes that work, you can count on Stairon’s expertise. We put collected data in to use and create growth.

By improving the way we manufacture our products, we can reduce life-cycle costs and environmental impacts. We also offer cost-effective prototyping.

A network for efficient delivery

We pack even large items with agility and according to customers special requests at Stairon’s extensive factory site. Our location in the industrial area of Pansio, in the middle of a ready-made infrastructure, reduces manufacturing and logistics costs. There is also a maritime route going directly from our factory site out to the rest of the world.

Stairon deliveries near and far

CHINA Lifting equipment

Improving the manufacturability of crane structures through robotic welding.

CHINA Paper and cardboard industry

Optimisation of production costs of product concepts using different manufacturing methods.

ARAB EMIRATES Paper and cardboard industry

Replacement of welded joints in product structures by bending to improve visual quality.

FINLAND Defence industry

Development of manufacturing technology for the automated production of structures for armoured transport vehicles.

WHICH COUNTRY? Energy Industry

Development of heat recovery systems.

Project management and reporting

Stairon offers personal service

To ensure project efficiency, we focus on customer understanding and good service. Whether the project is short or long, a competent project manager who understands the process requirements and the client’s needs is always in charge. In this way, we ensure that the work proceeds as agreed.

Familiar team

With us, you won’t be stuck at helpdesk. Continuity and personalisation are important added values for us. In addition to a dedicated account manager, each project has its own production team. In larger projects, there is also a project phase planner who shares responsibility and coordinates the work phases with the project manager. During the installation phase, we have worked on sites on all continents – except Antarctica.

Data on responsible production

Sustainability reporting also requires data on production. Not a problem for us. Continuous data collection provides customers with ready, valuable material for their own sustainability reporting. Data sharing is tailored to the needs of the client and the project. For us, sustainability is concrete actions.

Stairon deliveries near and far

Delivery of ready-to-use equipment and supply chain management in the uncertain circumstances of the pandemic.

INDONESIA Pulp industry

Manufacturing and supervision of the installation of pulp drying systems for one of the world’s largest pulp machines.

FINLAND Energy industry

Product-specific carbon footprint calculations for the customer.

USA Maritime industry

Coating work on the internal steel structures of cruise ship exhaust pipes using closed-circuit rope work.

USA Maritime industry

Manufacture and retrofit of exhaust gas scrubbers for Solstice class cruise liners while cruising.

Lifecycle services

Longer life cycle brings cost-efficiency

New is not the only option. Modernisation can also improve the features, reliability, safety and cost-efficiency of the equipment. In addition to complete modernisation, we also carry out partial modernisation, replacing individual components to meet your needs.

We are flexible to work either on our own or at the customer’s premises. By scheduling modernisation during downtime, we can make upgrades without impacting operational efficiency.

Repair and maintanance

Our experienced staff will plan and carry out repairs and maintenance, so that no time is wasted and no costs are overrun. We also provide flexible assistance in situations where one of our customer’s partners needs support in troubleshooting. We always provide a cost and time estimate for our work, on the basis of which we carry out the agreed work – independently or with a partner. For equipment with fast-wearing parts, we provide spare parts and installation service.

Stairon deliveries near and far

USA Maritime industry

Coating work on the internal steel structures of cruise ship exhaust pipes using closed-circuit rope work.

USA Maritime industry

Manufacture and retrofit of exhaust gas scrubbers for Solstice class cruise liners while cruising.

GERMANY Paper and cardboard industry

Extending the life cycle of 40-year-old heat exchangers through refurbishment to replace the need for new investment.

FINLAND Food industry

Lining and modification of internal steel structures of sea water tanks on site.

FINLAND Food industry

Product-specific carbon footprint calculations for the customer.

The five corner stones of our work

1

Exceptionally large modular production facilities

The large size and modularity of our facilities allow greater capacity for individual projects inspite of their duration. Additional space in our factory eliminates the need for extra logistics or external storage. Modularity and space means factories within a factory.

The five corner stones of our work

2

Material supply

Proactive material sourcing and in-house warehousing combined with in-house further processing significantly reduces delays in our customer projects. This means reliable delivery.

The five corner stones of our work

3

Data

Our experience and development in collecting production data facilitates sustainability and compliance reporting for our customers. Data sharing can be customised according to customer and project needs. To us, sustainability is concrete.

The five corner stones of our work

4

Experience and expertise

An adaptable production process and scalability allow for predictable project management, regardless of production volumes. Accurate simulation of all projects by production phase in advance provides predictability for scheduling and resource needs. Customers get what they order, at the agreed price.

The five corner stones of our work

5

Maritime access

Post-production logistics do not have to take place on land. Our production facilities have direct access to maritime routes, along which even large and oddly shaped equipment can be delivered anywhere in the world. To put it shortly – we’re located right by a port.

Equipment manufacturing for various industries with more than 2000 projects of experience

Our expertise is based on customer-oriented service and extensive expertise acquired over decades. We carry our responsibility by developing innovative and sustainable solutions that take into account both the environment and productivity. Our progressive approach creates profitable growth – for all parties involved.

Manufacturing technique

Technical manufacturing expertise and product knowledge for manufacturing equipment for a wide range of industries.

Responsible operations and certified quality

Extensive knowledge and expertise from acid-resistant special steels to aluminium alloys and from alloy steels to duplex steels.

Welding technology

Several joining methods that meet different international standards, from manual to automated welding.

Experienced staff

Skilled staff with over a thousand man-years of experience in equipment manufacturing and development.

Design collaboration

Design of manufacturing drawings from the customer's 3D model, as well as sizing and design of products such as various fans and heat exchangers.

Sandvik: "Stairon's facilities are perfectly adaptable to our needs, they have a flexible approach and strong industrial references."

Read more about the Sandvik collaborationWant to know more?

Book an apointment with our sales manager Antti Reivonen

“Stairon’s strength is its extensive expertise. We can order the whole package – both welding and installation.”

Read more about the Caligo Industria collaboration

Traveling around the world by maintaining cruise ship exhaust pipes

Read more about rope work in exhaust pipes