Based in Kaarina, Finland, Vema Lift supplies high-quality aerial platforms, specializing in top-tier products and innovations. Around 90 percent of the company’s revenue comes from exports, and since the late 1980s, it has delivered nearly a thousand lifting solutions worldwide.

The collaboration with Stairon covers all the most critical steel structures and aluminum work platforms, which are also pre-equipped to streamline production. Currently, the two companies are working together on a 90-meter aerial platform – a device that is remarkable not only for its height but also for its compact structure.

– The machine fits into a 12-meter transport length, which makes it exceptionally agile. At the same time, it offers the best performance values on the market in key features such as side reach and maximum permitted working load, says Ilpo Taulio, Purchasing Manager at Vema Lift.

Realizing these innovative solutions has required seamless collaboration in manufacturing and meticulous control over the strict quality and tolerance requirements in production.

– Our new product line reaches up to 114 meters, making Vema Lift the only manufacturer in the world offering aerial platforms at this size class.

Taulio emphasizes the importance of the company’s own strong design team in developing high-quality, pioneering products.

– Our partners also play a significant role. These devices are used for saving lives, so every part must be precisely manufactured and finished to the highest quality. That’s how we differentiate ourselves from the competition, Taulio says.

Demanding welding for demanding conditions

Certain critical joints and moving structures in aerial platforms are exposed to special loads and challenging conditions, requiring welding of exceptional precision and durability. As the platform ascends into the air, wind conditions also place additional strain on the structure.

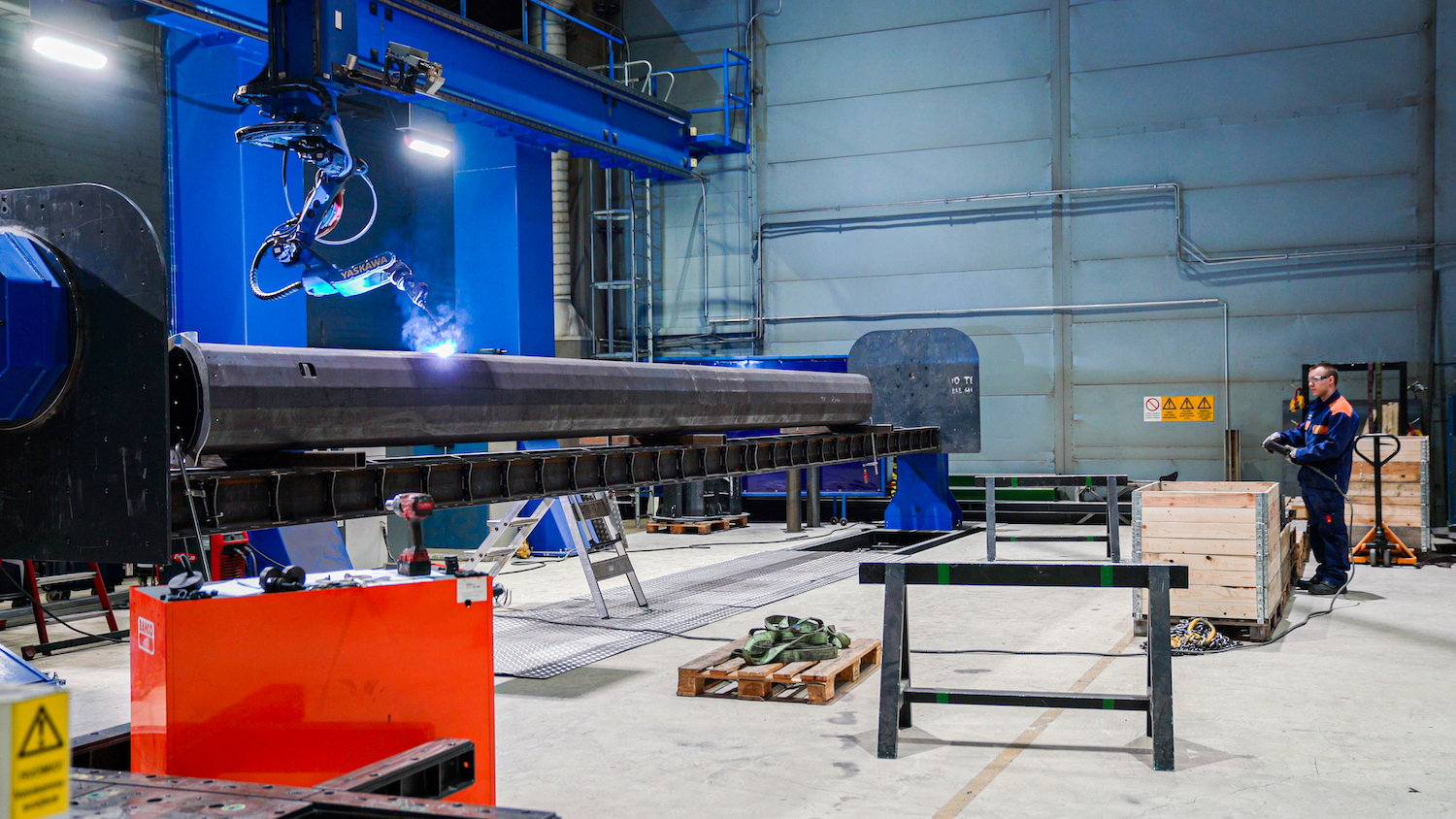

Each platform is assembled from several long boom sections. At Stairon, these parts are handled by a robot that performs the welding on the boom’s critical joints.

In boom welding, quality depends on the correct processing of high-strength steel: when welding several meters at a time, everything must be perfectly aligned. Controlling and optimizing the welding sequence is also a vital part of ensuring manufacturing quality.

– High-strength steel is a difficult material to work with because the heat input has to be exactly right – if the temperature is too high, the steel loses its properties, explains Stairon robot operator Tuomas Saarinen.

Stairon’s welding robot can, for example, precisely monitor momentary power – how much heat is being applied per millimeter and the resulting penetration depth.

– The robot ensures the weld is exactly as it should be on the inside. Doing the same job manually would be inefficient and practically impossible, Saarinen says.

Producing long components is one of Stairon’s core competencies.

– Together, we’ve also developed cost-efficiency through modularization, standardizing structures across different products. This speeds up both design and production throughput, adds Taulio.

A partner that enables growth

Vema Lift’s aerial platforms are built on truck chassis. These platforms have a long lifecycle: at their 10-year inspection, they undergo a full service, and the structures are built to last for decades.

Taulio notes that the technical features of aerial platforms have become increasingly important in recent years, and Vema Lift has a strong position in the market. The company also has ambitious growth targets.

– It’s essential for us that Stairon’s capacity and expertise allow us to scale up our production. We’ve been extremely satisfied with the quality of Stairon’s work and the entire partnership. These machines are very complex, and challenges always arise – but Stairon has the ability to solve them quickly, Taulio says.

Vema Lift Oy

Founded: 1989

Revenue: 6,8 M€

Employees: 38